In recent years, airless system solutions for cosmetic brands have been growing. An understandable fact since it is essential to protect formulas through its engineering, keeping active ingredients and natural microencapsulated formulas safe. Now, clean beauty is one of the most concerning trends, so we go further on this topic.

Do you consider important to protect and enhance your formulas in a sustainable way? I hope so because nowadays is no longer an option. Many brands are launching more natural treatment formulas with organic ingredients that require airless packaging solutions. These beauty brands realized that the packaging must also be sustainable and recyclable, and they are making huge efforts to be more eco-conscious.

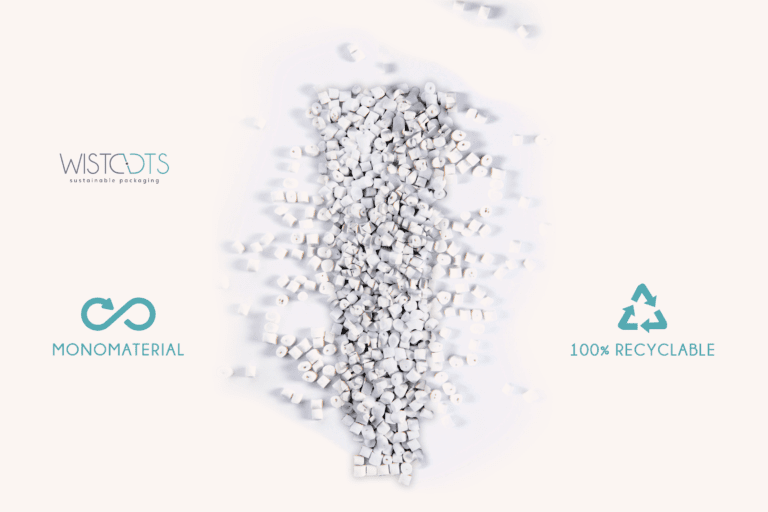

WISTADTS has mono-material airless systems options available to meet the high demand of eco-friendly brands for this type of issues. Made only of polyethylene, including a bio-based option that was designed to be easy to use.

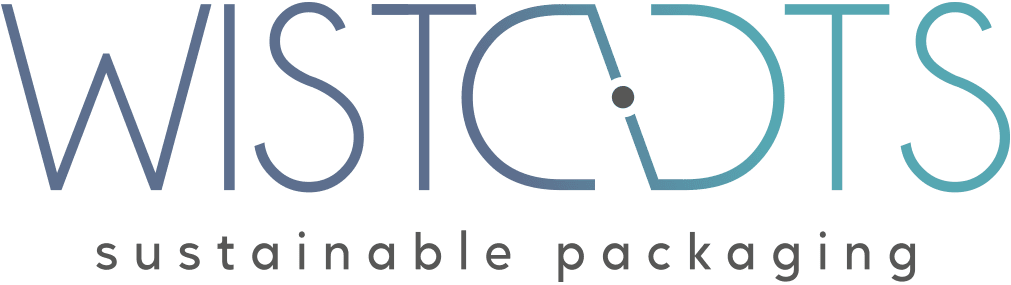

Aquamarine

This is a pump mono-material airless system solution, perfect for natural treatment formulas such as treatment lotions, creams or formulas with vitamin C. This concept was designed to enhance your product through a rigid piston airless system and beautiful-looking tube. And because the protection of your formulas is always one of our concerns, Aquamarine allows microencapsulated ones to pass through without braking and without clogging the system.

SAGE® Airless System

SAGE® Airless System is very popular among our business partners for formulas that require precision on the application and do not need a pump. A mono-material airless system that is easy to fill, without changing standard filling lines, which was designed with an internal one-way valve that controls the flow, blocking the air from returning into the tube. With it, your formulas are protected from oxidation, reducing the need of using preservatives.

UD Pump Airless System

If you are looking for a lightweight mono-material airless pump and you have challenging formulas, the UD pump is perfect for your products. Preserving and enhancing the integrity of your formulas, this option allows microcapsules to break only after contact with skin. Challenging formulas that often contain high levels of mineral physical barriers usually clog most pump systems. The UD pump technology allows these large particles to pass through the system without clogging it.

All the technological airless systems described above are 100% recyclable and do not require disassembly. They are mono-material, made just with polyethylene with a sugarcane-based resin option.

As we have discussed in this post, ecological and sustainable focus is no longer an option. With these solutions you can provide a good user experience and leverage your business. To find the key for your needs, contact us.